Concrete Crushers

Concrete Crushers | Concrete Pulverizers

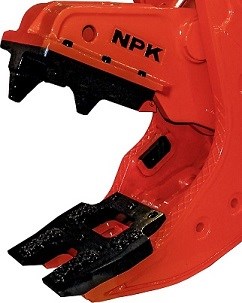

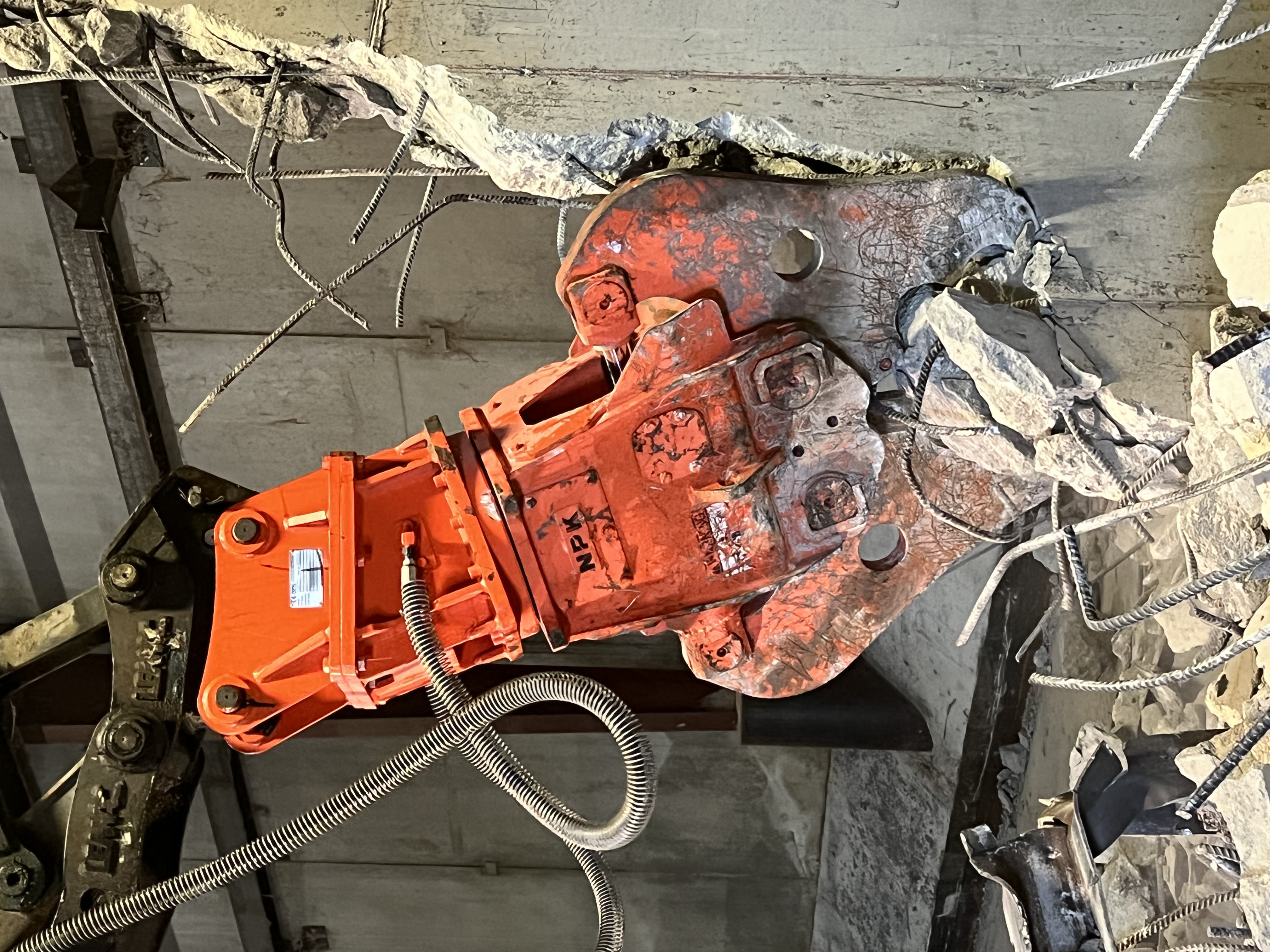

NPK's Primary/Secondary Concrete Crushers are designed to effectively handle any primary and/or secondary demolition and recycling operation.

NPK concrete pulverizers easily crush through reinforced concrete and cut through light steel structures allowing material to be separated and recycled, and simultaneously, permits easier handling of material.

Maximum crushing/cutting force with more efficiency

Competitive cylinder systems need larger cylinders to equal the force developed by the more compact NPK intensifier system. On the job, NPK's exclusive integral hydraulic intensifier system provides faster cycle times compared to competitive units using larger cylinders that require considerable amounts of flow to produce an equal amount of productivity; thus producing the shortest cycle time in the industry.

Designed for performance

With the tooth configuration utilizing a high-profile center tooth and lower profile teeth on both sides of the movable jaw, NPK concrete pulverizers can be used for both primary and secondary crushing operations. Abrasion-resistant, high-strength, alloy steel teeth provide decreased wear and increased durability. In addition, the "R" models come with full 360° hydraulic rotation for maximum versatility.

Designed for easier maintenance

In addition to the bolt-on replaceable tooth plate on the movable jaw, all “A” models utilize a bolt-on replaceable plate on the corresponding portion of the fixed jaw. The new design decreases downtime due to repairs while increasing the life of the crusher. Cutting-torch operations are eliminated by a replaceable high-strength, steel center cutter that slices through rebar and light steel structures.

Faster, more efficient separation of concrete and steel rebar

Powerful concrete crushing forces increase when jaws meet resistance, as the exclusive NPK cylinder intensifier converts flow to pressure.

NPK dedicated mounting kits enable concrete crushers to be mounted as excavator attachments for carriers within the recommended weight range for each model. See the Attachment Wizard to determine which NPK hydraulic attachments are compatible with your carrier.

Potential applications include:

- Construction and Demolition (C&D) recycling / sorting

- Concrete recycling

- Commercial demolition

- Separating concrete from rebar

X-Series (Suited for smaller carriers 4 -14 METRIC TONS)

- Well suited for smaller carriers that can fit into tight spaces, ideal for internal demolition

- Favorable power-to-weight ratio with slim and compact design

- Simultaneously closing jaws with replaceable carbide teeth and integrated cutting blades

- Cylinder with integrated booster

- Hydraulic components and hoses protected inside the crusher’s frame

- Fast opening / closing cycles with constant force

- Full 360° rotation - 3 rotation options available for X-Series: mechanical/free, full hydraulic or electro-hydraulic

Visit and subscribe to NPK's YouTube channel for videos of concrete pulverizers in action!

Visit NPK's photo website for searchable concrete pulverizer photo galleries!

Visit the Concrete Crusher Publications page for sales brochures and operation & maintenance manuals.

Visit each concrete crusher model page below for additional images and specifications. If you require a booster service manual or would like a hard copy of the operation and maintenance manual, please contact the Sales department at 440-232-7900 or by email at sales@npkce.com.

| Image | Model | Recommended Carrier Weight | Rotation | |

|---|---|---|---|---|

|

U21JA | 42,000 - 62,000 lb | fixed |

|

|

U21JRA | 42,000 - 62,000 lb | 360° hydraulic rotation |

|

|

U31JA | 62,000 - 106,000 lb | fixed |

|

|

U31JRA | 62,000 - 106,000 lb | 360° hydraulic rotation |

|

|

U45J | 90,000 - 110,000 lb | fixed |

|

|

U45JR | 90,000 - 110,000 lb | 360° hydraulic rotation |

|

|

X-4AFR | 9,000 - 12,000 lb | 360° mechanical/free rotation |

|

|

X-4AR | 9,000 - 20,000 lb | 360° hydraulic rotation |

|

|

X-4AREH | 10,000 - 20,000 lb | 360° electro-hydraulic rotation |

|

|

X-7AFR | 13,000 - 20,000 lb | 360° mechanical/free rotation |

|

|

X-7AR | 13,000 - 31,000 lb | 360° hydraulic rotation |

|

|

X-7AREH | 13,000 - 31,000 lb | 360° electro-hydraulic rotation |

|

|

V250R | 53,000 - 77,000 lb | 360° |

|

GOOGLE TRANSLATOR

GOOGLE TRANSLATOR